HEXTRONICS

HEXTRONICS

28 DECEMBER 2024

28 DEC 2024

eNGINEERING eXCELLENCE: iNSIDE THE mACHINES THAT tEST hEXTRONICS' lIMITS

eNGINEERING eXCELLENCE: iNSIDE THE mACHINES THAT tEST hEXTRONICS' lIMITS

eNGINEERING eXCELLENCE: iNSIDE THE mACHINES THAT tEST hEXTRONICS' lIMITS

In the realm of advanced electronics, reliability and resilience are non-negotiable. Hextronics takes the commitment to performance seriously, utilizing a specialized testing machines to simulate extreme stress and identify the long-term durability of wires used in our stations.

In the realm of advanced electronics, reliability and resilience are non-negotiable. Hextronics takes the commitment to performance seriously, utilizing a specialized testing machines to simulate extreme stress and identify the long-term durability of wires used in our stations.

In the realm of advanced electronics, reliability and resilience are non-negotiable. Hextronics takes the commitment to performance seriously, utilizing a specialized testing machines to simulate extreme stress and identify the long-term durability of wires used in our stations.

mANUFACTURING ENGINEER, dANIEL rICHTER, EXPLAINS THE TESTING MACHINES BUILT TO IMPROVE THE QUALITY OF OUR DRONE STATIONS

[music: V - AKIRA SORA, freemusicarchive cc by-nc]

mANUFACTURING ENGINEER, dANIEL rICHTER, EXPLAINS THE TESTING MACHINES BUILT TO IMPROVE THE QUALITY OF OUR DRONE STATIONS

[music: V - AKIRA SORA, freemusicarchive cc by-nc]

mANUFACTURING ENGINEER, dANIEL rICHTER, EXPLAINS THE TESTING MACHINES BUILT TO IMPROVE THE QUALITY OF OUR DRONE STATIONS

[music: V - AKIRA SORA, freemusicarchive cc by-nc]

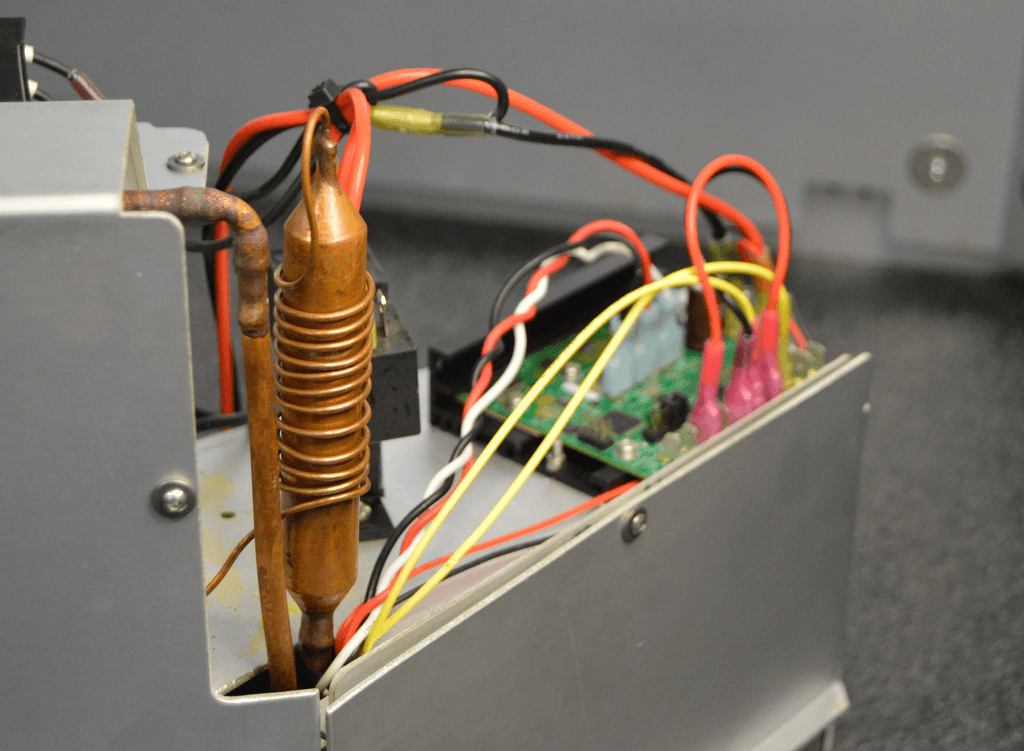

Daniel Richter, in charge of Hextronics' electrical-mechanical design and our manufacturing engineer, creates these testers to identify the best materials to use as well as areas in need of improvement. He designed a 3D-printed mechanism which bends different wires continuously to recognize the point of failure, as well as compare durability of alternate wires. The stress-tester simulates the life of a wire in the Universal and Atlas drone stations, constantly moving and bending. Each wire must provide the required current and sustain uninterrupted performance to ensure the drone station is always ready when necessary. There are countless wires incessantly operating in the drone stations, if just one wire were to fail the entire system would be ineffective in immediate response situations.

relentless testing for uncompromising performance

relentless testing for uncompromising performance

relentless testing for uncompromising performance

Stress-Testing components for Long-Term Reliability

Stress-Testing components for Long-Term Reliability

The machine is designed to bend, twist, and stress-test wires relentlessly until they fail. This process replicates years of wear and tear in a controlled, accelerated environment, allowing engineers to evaluate how well materials stand up to the challenges of time and use. The resulting data plays a critical role in refining wire selection and ensuring that Hextronics’ systems remain operational under even the most demanding conditions.

The machine is designed to bend, twist, and stress-test wires relentlessly until they fail. This process replicates years of wear and tear in a controlled, accelerated environment, allowing engineers to evaluate how well materials stand up to the challenges of time and use. The resulting data plays a critical role in refining wire selection and ensuring that Hextronics’ systems remain operational under even the most demanding conditions.

The machine is designed to bend, twist, and stress-test wires relentlessly until they fail. This process replicates years of wear and tear in a controlled, accelerated environment, allowing engineers to evaluate how well materials stand up to the challenges of time and use. The resulting data plays a critical role in refining wire selection and ensuring that Hextronics’ systems remain operational under even the most demanding conditions.

This rigorous testing protocol underscores Hextronics’ dedication to quality. For industries where dependable connections are crucial—such as drone-in-a-box deployments—every detail counts. By understanding a system’s breaking point, the engineering team can create solutions that maintain reliability even in extreme environments. As Hextronics continues to innovate, these testing machines serve as the cornerstone of our commitment to excellence. It ensures that every system meets the highest standards of durability, paving the way for technologies that clients can trust.

This rigorous testing protocol underscores Hextronics’ dedication to quality. For industries where dependable connections are crucial—such as drone-in-a-box deployments—every detail counts. By understanding a system’s breaking point, the engineering team can create solutions that maintain reliability even in extreme environments. As Hextronics continues to innovate, these testing machines serve as the cornerstone of our commitment to excellence. It ensures that every system meets the highest standards of durability, paving the way for technologies that clients can trust.

This rigorous testing protocol underscores Hextronics’ dedication to quality. For industries where dependable connections are crucial—such as drone-in-a-box deployments—every detail counts. By understanding a system’s breaking point, the engineering team can create solutions that maintain reliability even in extreme environments. As Hextronics continues to innovate, these testing machines serve as the cornerstone of our commitment to excellence. It ensures that every system meets the highest standards of durability, paving the way for technologies that clients can trust.

OUR PARTNERS

OUR PARTNERS

OUR PARTNERS